BREAKAWAY COUPLINGS

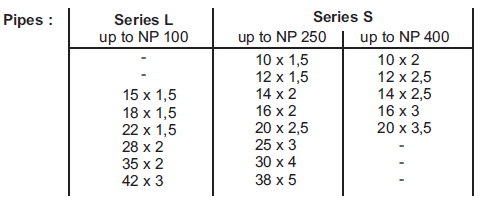

General :- • breakway couplings are manufactured in two series

• Light seried = L heavy series = S

• Non standard dimensions and breakway couplings for higher

Pressures on demand.

• Absoute reliablity can only be guaranteed for EO- pipe couplings if

EO- parts are exclusively used and if they are fitted in accordance

with the instructions.

• Fitting instructions for workshops may be had on demand (TM.)

Standardization: • Breakway couplings are delivered according to DIN 3930 (summary ). In case of screw-in couplings, which are provided for both with metrical thread and also with Whitworth thread, the latter should be preferred on account of its wide use internationally. screw-in oles see page A 15 and A 16.

• Material and Surface Protection:In general EO- breakway couplings are manufactured of steel for steel pipes.

• Nuts and bodies : steel, drawn or forged phosphated and oiled.

• Cutting and locking rings as well as pressure rings : steel

cadmiumplated.

• Other materials or surface protection on demand.

Pressures and pipe recommendations :

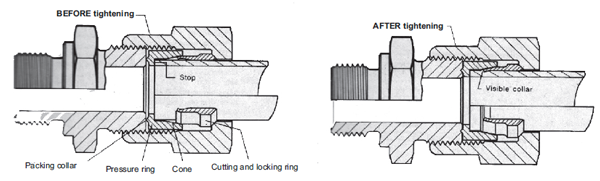

The preformed hard cutting and locking ring, when tightening the nut, slides

along the cone of the pressure ring, tapers off and cuts into the tube while

throwing up a visible collar. At the same time the packing collar on the pressure

ring presses itself into the socket. It is absolutely necessary that the tube

koocks against the stop in the cone, as otherwise the cutting operation cannot

be performed.

The preformed hard cutting and locking ring, when tightening the nut, slides

along the cone of the pressure ring, tapers off and cuts into the tube while

throwing up a visible collar. At the same time the packing collar on the pressure

ring presses itself into the socket. It is absolutely necessary that the tube

koocks against the stop in the cone, as otherwise the cutting operation cannot

be performed.

An essential condition is a correct first fitting. The fitting instructions on page E

3 give detailed information of the points which must be observed and of the

sequence of the fitting.